Full of Compressed Air

I inherited a nonworking industrial air compressor. Naturally, I spent an irrational amount of time and effort restoring it to working condition.

Question: What do you feel when you come across a piece of machinery that no longer works? Do you feel sadness that it’s not able to fulfill its potential? Confusion as to why it isn’t working as it should? Anger that some kind of engineering injustice is being inflicted upon you, it, and the world? Joy that this is proof that machines will not rise up and challenge humanity for supremacy? Or nothing? Maybe you feel nothing because it’s just a machine and this is kind of stupid and there are more important things in the world.

I think most people probably go with “nothing,” because they are normal, well-adjusted people with better things to spend their time thinking about. Not me, though. I feel compelled. Compelled to see the machine returned back to its rightful working state.

And that’s why I spent too much time and too much money resurrecting an old air compressor.

First I should say that my compulsion isn’t based on some new-age notion that machines have some kind of sentience or soul and “deserve” to live. I just hate seeing things go to waste. We live in a throw-away society and it really kills me. So much trash, so much litter, so little pride in what we create.

Therefore, when I come across something like an air compressor from decades past, I desperately want to restore it to a functional state rather than see it get added to a pile of junk and replaced by some poor plastic substitute.

Plus, I might just learn something along the way.

The Green Monster

When we bought our house last year, the previous owner left behind a variety of things — an old leaf blower, a drop spreader, a smoker, hardwood planks, and a huge, dark green air compressor I took to calling “The Green Monster."

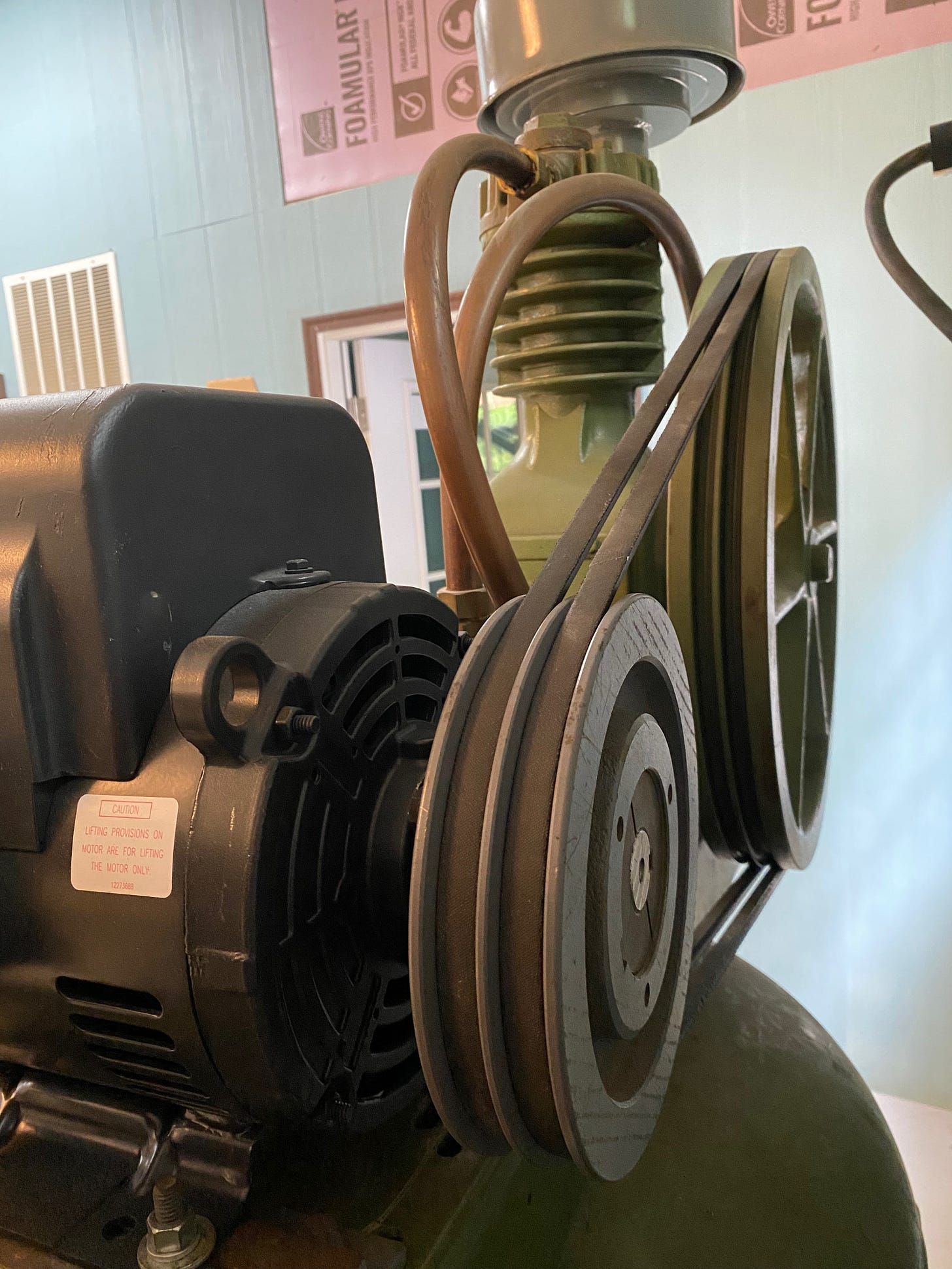

The Green Monster sat in the corner of our “yard barn.” One day I flicked it on and it coughed and shook and reluctantly came to life. As the motor turned and belts tugged on the pump’s pully, I watched the pressure gauge slowly tick upward. My curiosity sated for the moment, I flicked the machine off and ignore it while I attended to other more pressing concerns.

The truth is, I’ve always had a crush on air compressors, if that can be a thing. As a kid, I’d get flat tires on my bike and wish we had an air compressor to speed my fix. Same with blowing up footballs or soccer balls or rafts or air mattresses. Later, as a teen driver, I was overly concerned with ensuring my tires were always perfectly inflated.

And then there were pneumatic tools. Nail guns, paint sprayers, impact wrenches — all powered by compressed air. I mean, who wouldn’t want a kick ass air compressor??

Oh, how an air compressor would have saved me countless trips to the gas station or prevented me from getting light headed when blowing up balls or allowed me to repeatedly fire nails into wood. Alas, it was never meant to be.

But now I had an air compressor of my very own and I was excited to use it. After a few months of neglect, I returned to the yard barn and flicked the switch on again. Only this time, nothing. No cough. No shake. No noise. No nothing.

Diagnostics

It was surprising that The Green Monster, which had seemed to work perfectly earlier in the year, was now nonfunctional. Did I break it somehow? Did someone else?

To find out, I unplugged the machine from its 220-volt outlet and diassembled the starter switch. I took everything apart to try to see if something was obviously wrong — a loose wire, a scorch mark, a note from an international terrorist. But everything looked fine. Maybe the switch itself had gone bad, I wondered. Luckily, I happened to have another one just like it that I had removed from our well pump system. (Short story: our well pump died and when we replaced it, we no longer needed a two-wire switch to operate it, so I removed it from the system and set it aside in case it came in handy for some other purposes. Lo and behold!)

After swapping out the switch, I was able to get the air compressor to run, but only for a short time and not without smoke rising from the switch — a fairly obvious bad sign.

My instinct told me that the problem might be the motor, then. Perhaps it was drawing too many amps and overloading the switch. With my multimeter, I tested this theory and found it was spot on. So, a failing motor must have burned out the first switch and would do the same to this replacement unless I fixed the motor.

The motor was mounted to the top of the compressor and was fairly easy to unbolt. But actually removing it proved slightly more challenging, since it weighed at least 75 pounds.

Eventually I got it off the compressor and into my truck. I looked up an electric motor repair shop and took it in, hoping it could be diagnosed and, if necessary, fixed.

Sure enough, the shop was able to diagnose the problem: It was shot. Completely. But, it could be fixed; It just needed to be re-wound. They’d happily do it for $2,000.

“Uh, and how much would a new motor be,” I asked.

“Seven hundred dollars.”

Three things about this. One, why did they bother telling me I could repair the existing motor for $2,000 instead of just going right to the $700 replacement? Second, $700 is definitely better than $2,000, but also, a brand new air compressor of similar size to The Green Monster would cost between $800 and $1,000. So it seemed foolish at best to spend a similar amount fixing the Monster. And third, I actually already have a working air compressor. It’s a small, portable one. But it works fine. It’s great, actually. Quiet, needs no oil, works beautifully. So just how stupid am I for thinking I should fix this one? Pretty stupid, I guess.

So I declined the repair and asked if the motor had any scrap metal value. They said no, it didn’t. So I made plans to pick up the motor (for what reason, I do not know) and think about my next steps.

On the Hunt

I pretty much forgot about The Green Monster for a few months and let the motor sit in my garage while I attended to other matters. My main concern was organizing and then getting rid of various debris that had been scattered around the property or from structures I was removing — fencing, a slide, etc. I ended up with quite a collection of fence posts, metal utility poles, wire fencing, and other assorted metal and wood. Some of the wood I salvaged for future use in the shop. Lots of items I managed to sell on craigslist. But I also had hundreds of pounds of metal that I needed to take to the local scrapyard, including the old air compressor motor.

Scrapping metal doesn’t pay the bills — unless you have metric tons of it — but it did prompt me to turn back to The Green Monster. Should I just scrap the lifeless thing and get a few bucks (maybe $20 or $30 if I was lucky), or should I try once more to breathe new life into it?

Of course I decided on the latter. (BTW, I got about $40 from a local scrapyard for the motor) The first course of action was looking to see if I could find a suitable replacement motor. In a fit of stupidity, I called the first company back and asked about the $700 motor. They said the price had gone up. To what, I asked. Fifteen-hundred dollars. FFS!

Ok, what about Harbor Freight? They have motors that seem like they’d work and for far less than I had previously been quoted. But upon further inspection, I discovered they wouldn’t fit my air compressor.

I didn’t know — but of course this would be the case — that motors come in an almost endless array of specifications, often denoted by a Frame Type. Horsepower, phases, spindle diameter, RPM, rotation direction, voltage, location of bolt holes and more all have to be considered.

Eventually I figured out what the specs of my old motor were and set about finding a match. Prices ranged from the high to the obscene, and that didn’t include freight charges for shipping. It was getting harder and harder to justify this venture when I stumbled upon a match at Grainger that was reasonably priced, all things considered. I placed my order and was told to expect it in three to five weeks.

Moving the Monster

While waiting for the motor to arrive, I decided I wanted to move the Monster from the yard barn to the shop. It wouldn’t be easy, I knew, but I figured I could do it if I was careful and used straps and a hand truck. Turns out I was wrong. Although I managed to extract it from the yard barn, maneuvering it across the stone driveway proved to be beyond my capabilities and the whole thing fell to the ground. It was far too heavy for me to lift by myself.

Out of desperation, I called a former neighbor and asked if he (and his teenage son) was available to lend me a hand. They were and drove the more than 30 miles (one way!) to help me lift and move the Monster into the garage. I was beyond grateful, though I think they may have since blocked my number on their phones.

Since the Monster runs on 220 voltage, I had to install a new breaker in the garage’s electrical panel and run a new line to a new 220 outlet. I also had to replace a couple of parts and re-plumb some of the lines to accommodate its new location.

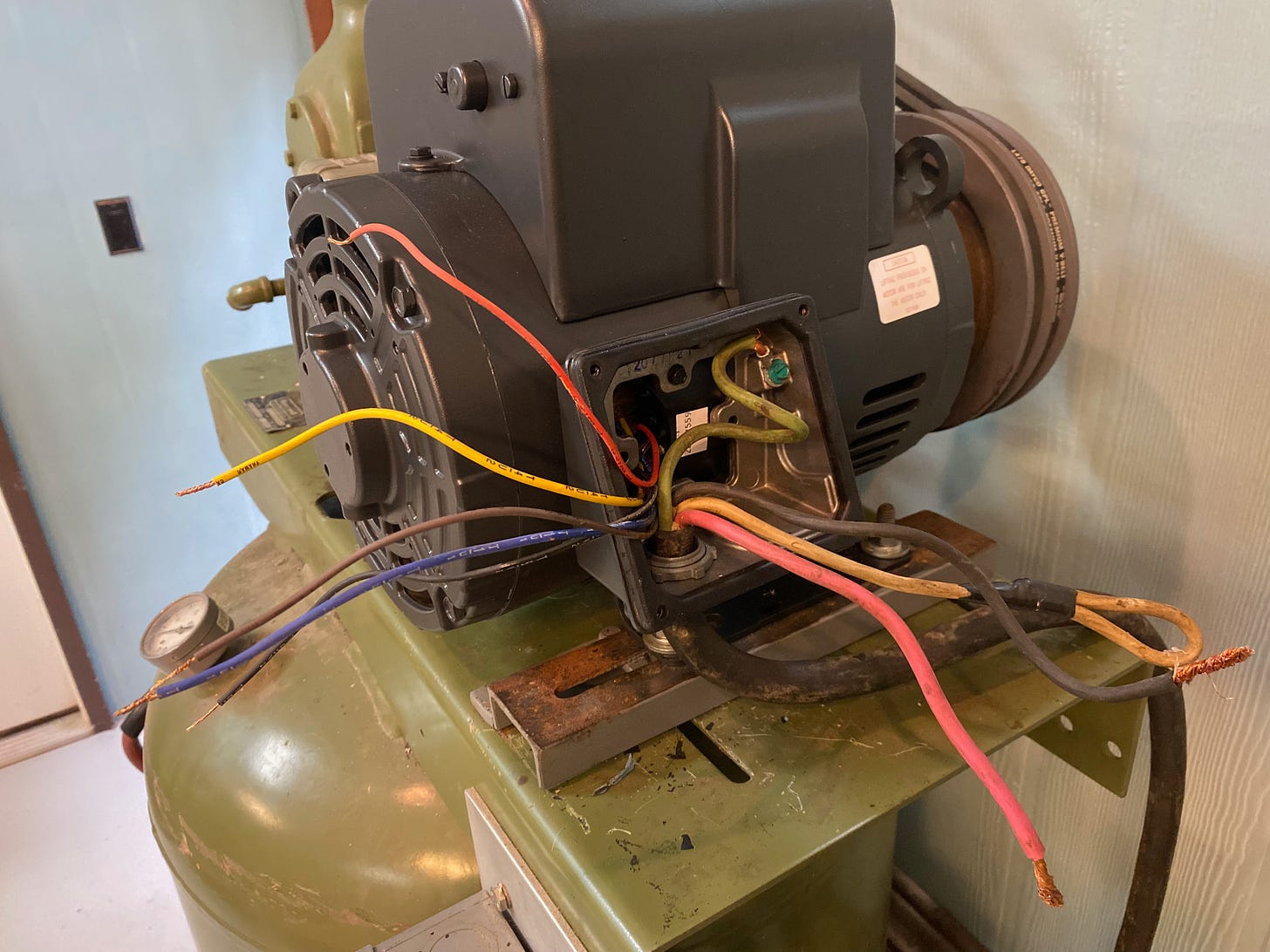

After a few weeks, the motor finally arrived. I lifted it into place, wrangled the belts around it and then re-wired the connections, grateful that I had the wherewithal to take pictures of the previous motor’s wiring before I disassembled it.

It took me a few minutes of finagling, but soon everything was set and ready. I plugged the Monster in and flicked the switch. The new motor purred to life and the compressor was humming. I was beaming.

So, was it worth it? Does the Green Monster earn its keep? Hell yes! Inflating tires, inflating balls, blowing dust off machines, connecting pneumatic tools — it does it all!

Maybe my compulsion to get it fixed was financially irrational, but emotionally it was spot-on. I kept it out of the trash heap, find almost daily uses for it, and learned a few things along the way. What could be better than that?